System Description:

Electrothermal propeller de-icing pads are bonded to the root leading edges of the propeller blades.

When (PROP HEAT) is switched on, power is supplied to the de-ice pads on all three of the propeller blades on one engine for 90 seconds. Each pad draws approximately 5 amps, so if all three pads are functioning correctly, approximately 14 to 18 amps will be used.

After 90 seconds, power switches automatically to the blades on the other engine which, in turn, will be heated for 90 seconds. This sequence continues until power is switched off, but it is not possible to tell which engine blades are being heated at any particular moment in time.

This power sharing arrangement provides sufficient heating to continuously de-ice both engines, but limits the current drawn to only about 15 amps – heating all six blades simultaneously would overload the alternators.

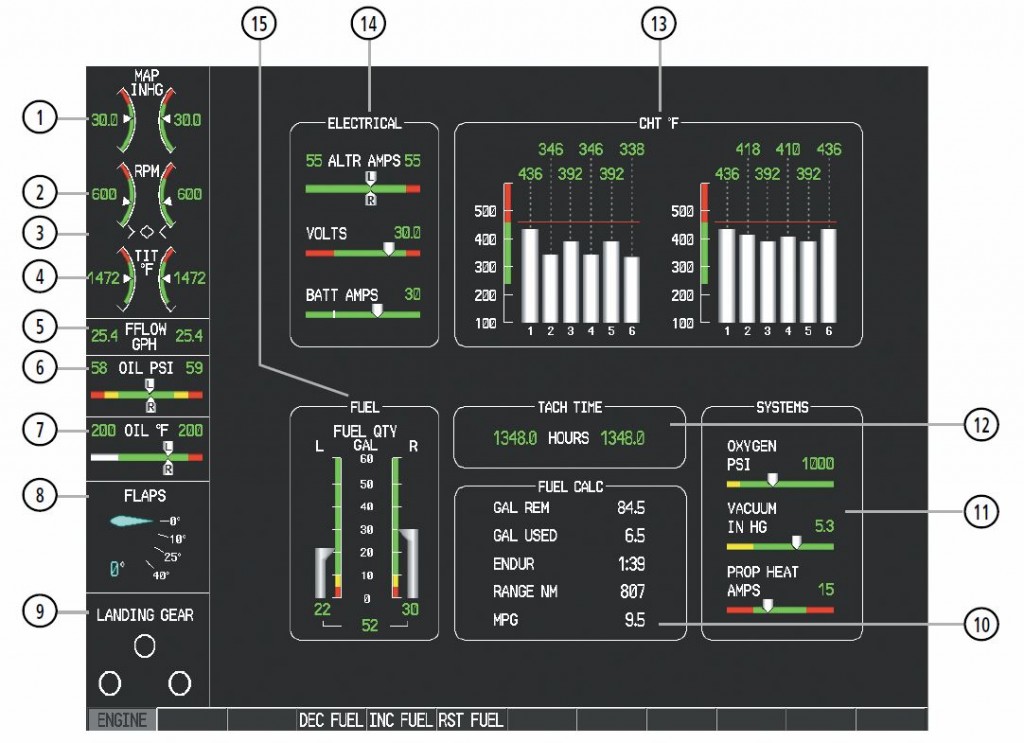

In the picture above of the MFD ENGINE page, the PROP HEAT AMPS gauge (in the SYSTEMS item – 11) is indicating that the PROP HEAT is switched in and functioning correctly on one of the engines – you cannot determine which.

Switching off the PROP HEAT, then immediately switching it back on again will instantly swap power to the pads on the other engine. This provides a way of rapidly testing the PROP HEAT system before flight without waiting 90 seconds for the system to swap engines automatically.

If one or more of the pads fails to supply sufficient heat, the PROP HEAT AMPS gauge may indicate only 5 or 10 amps and fall into the red area. This should generate a red PROP HEAT FAIL warning message on the CAS and an associated aural alarm.

System Use:

There are no limits to use of the PROP HEAT on the ground.

If flight in icing conditions is suspected, the system must be tested during the After Start checks. Although, the QRH and SOPs do not specify exactly how the test should be performed, the Piper POH specifies that system should be tested for just 10 seconds, but this may not be sufficient to test that all 6 pads are working effectively.

Therefore, best practice is that you either:

- Switch on the PROP HEAT and leave it on for at least 90 seconds to ensure that the system swaps power automatically to the second engine, monitor the PROP HEAT AMPS gauge and ensure that no warnings occur.

- Or, switch on the PROP HEAT, monitor the PROP HEAT AMPS gauge for 10 seconds to ensure that no warnings occur, then cycle the PROP HEAT switch off/on and monitor the second engine for at least 10 seconds.

If icing conditions are encountered in the air, immediately switch on the PROP HEAT and leave it on until leaving icing conditions. There are no performance reductions associated with the use of PROP HEAT.

Warnings:

During operations in icing conditions, it is possible that a de-icing pad might fail on one of the propellers. A red PROP HEAT FAIL warning on the CAS should be generated if this happens, but if the pad only partially fails, it may not.

If a red PROP HEAT FAIL warning on the CAS occurs whilst in the air, switch off the PROP HEAT, then exit and avoid icing conditions. There is a danger that continued operation in icing conditions under these circumstances will lead to ice forming on the unprotected blade and producing an unbalanced propeller. This will cause excessive vibration that could result in an engine failure.

If excessive vibration is encountered in icing conditions with the PROP HEAT switched ON, exercise the propeller on the affected engine and check the PROP HEAT AMPS indication on the MFD Engine page. If the vibration persists, it is possible that one pad has only partially failed; therefore, switch the PROP HEAT off and exit icing conditions as soon as possible.