System Description:

Although not solely for use in icing conditions, the engine alternate air supply is used in the icing drill. The engine air induction system receives ram air through a flush inlet located on the right side of the lower cowling.

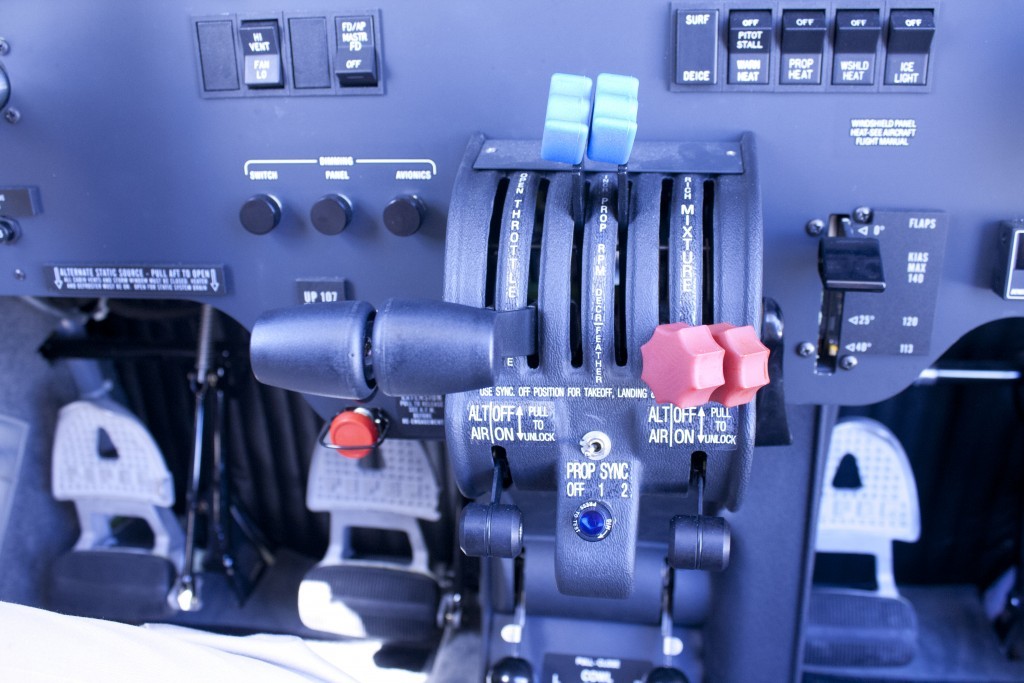

Air enters this inlet and flows through a removable air filter located in an airbox which is an integral part of the cowling. The filter removes dust and other foreign matter from the induction air. However, in the event that the flush inlet or filter becomes obstructed by ice or other causes, the pilot must manually select alternate air (ALT AIR) to ON (lever down) to bypass the filter and allow induction air to be taken from inside the engine cowling.

In addition to opening the alternate air door, selecting ALT AIR to ON also closes off cooling air to the induction aftercooler thus providing additional heat to the induction air and preventing ice from forming in the system.

Performance Implications:

Selecting ALT AIR to ON has two drawbacks:

- Allowing unfiltered air to enter the engine can reduce engine life. It is therefore important to select ALT AIR to OFF when on the ground (unless being tested during the Power Checks).

- There will be a slight loss of manifold pressure that becomes more significant at high altitude when the turbocharger wastegate is closed. A loss of up to 5″ MAP is possible at maximum continuous power settings with perhaps greater loss at cruise power settings.

Operational Use:

Select ALT AIR to ON if ice is seen to be forming on the aircraft leading edges.

Select ALT AIR to OFF once ice is no longer forming or before landing.